- Lathe

- Mochine o nang le merero e mengata

- Deep Hole Boring And Honing Compound Machine

- Mochini oa ho phunya le ho cheka ho tebileng

- Mochini oa ho Cheka Sethunya se Tebileng

- Deep Hole Honing Machine

- Mochini oa Deep Hole SRB

- Mochini o Fetolang le oa ho Boring o Tebileng

- Sesebelisoa sa ho itšeha sekoti se tebileng

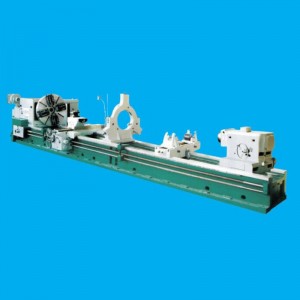

Horizontal Engine Lathe

-

enjene e rapameng e tloaelehileng lathe CW6163E,CW6180E,CW61100E,CE61200E

Bethe ea lathe ke ea mofuta oa fuluru ea bohlokoa.E entsoe ka botlalo.Ka mor'a ho lahla le ho sebetsa ka thata, e tlas'a phekolo ea botsofali ho netefatsa ho tiea ha mohaho oa mochine oohle.Tsela ea tataiso e tlas'a ho tima maqhubu a mahareng, boima ha bo ka tlase ho HRC52, botebo bo thata ha bo ka tlase ho 3mm, 'me botsitso ba mochini oohle bo botle.

Sebopeho se utloahalang sa moralo se tiisa hore lathe e na le botsitso bo lekaneng le bo tsitsitseng.Theknoloji e tsoetseng pele e tiisa hore mochine o na le boleng bo botle, lerata le tlaase le ho sisinyeha ha nyenyane.

Ponahalo e ntle, e kopantsoeng le melao-motheo ea ergonomic, phetoho e bonolo ea lisebelisoa tsa mosebetsi, ts'ebetso e bonolo le tlhokomelo.

Likarolo tse ka sehloohong tse kang bethe, hlooho, koloi le tailstock li entsoe ka lisebelisoa tsa boleng bo phahameng ba lehlabathe la resin.Ka mor'a botsofali ba tlhaho le botsofali ba maiketsetso, likarolo tse ka sehloohong tsa mochine li tiisetsoa hore li na le deformation e tlaase le botsitso bo phahameng.

Spindle e nka sebopeho sa ts'ehetso e meraro, e nang le bolelele bo lekaneng, lerata le tlase, tlhahiso e tlase ea mocheso le ho boloka ho nepahala.

Spindle e na le lebelo le pharaletseng la lebelo, ts'ebetso e tsitsitseng, ho phahama ha mocheso o tlase le ho boloka ho nepahetseng hantle.

Sesebelisoa se seholo sa phetisetso se thatafalitsoe ebile se fatše ho netefatsa ho nepahala ha eona ho phahameng, ts'ebetso e boreleli le lerata le tlase.

Matla a phahameng a ho itšeha le ts'ebetso e phahameng ea ts'ebetso.

-

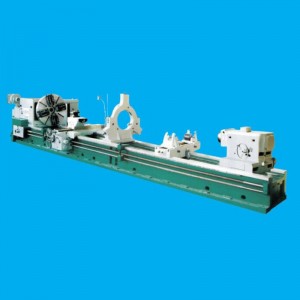

rapameng enjene lathe CWA61100-CWA61160

Sesebelisoa sena sa mochine ke lathe e tloaelehileng ea bokahohleng, e loketseng ho fetola selikalikoe se ka ntle, sefahleho sa ho qetela, grooving, ho itšeha, ho bora, ho fetola sekoti se ka hare, khoele e fetolang le mekhoa e meng ea likarolo tsa shaft, likarolo tsa cylindrical le poleiti ea lisebelisoa tse fapaneng tse nang le lisebelisoa tse phahameng. lebelo la tšepe le lisebelisoa tsa tšepe tse thata tsa alloy.The spindle e nka sebopeho sa litšehetso tse tharo, 'me bethe e nka bethe ea bohlokoa, e le hore bethe e be le botsitso bo phahameng,' me apron, poso ea lisebelisoa le saddle li ka tsamaea kapele.Sesebelisoa sena sa mochine se na le molemo oa ho tiea ho matla, ts'ebetso e phahameng, e sireletsehileng le e ka tšeptjoang, e bonolo ho sebetsa le e ntle ka ponahalo.

-

rapameng enjene commonal lathe CW6163,CW6180(A),CW61100(A),CE61200(A)

Sesebelisoa sena sa mochini ke enjene ea bokahohleng, e loketseng ho fetola selikalikoe se ka ntle, sefahleho sa ho qetela, grooving, ho itšeha, ho bora, ho fetola lesoba le kahare, khoele e thibang le lits'ebetso tse ling tsa likarolo tsa shaft, cylindrical le likarolo tsa poleiti ea lisebelisoa tse fapaneng tse phahameng. -speed steel and hard alloy steel tools.The spindle e nka sebopeho sa litšehetso tse tharo, 'me bethe e nka bethe ea bohlokoa, e le hore bethe e be le botsitso bo phahameng,' me apron, poso ea lisebelisoa le saddle li ka tsamaea kapele.Sesebelisoa sena sa mochine se na le molemo oa ho tiea ho matla, ts'ebetso e phahameng, e sireletsehileng le e ka tšeptjoang, e bonolo ho sebetsa le e ntle ka ponahalo.

-

rapameng enjene tloaelehileng lathe CW61128-CW611208

Letoto lena la li-lathe tse tloaelehileng tsa enjene li ka etsa mesebetsi e fapaneng ea ho fetola.E ka fetola selikalikoe se ka ntle, lesoba le ka hare, sefahleho sa ho qetela, khoele ea metric, khoele ea inch, modulus le khoele ea sekontiri le likarolo tse ling tse bōpehileng ka likarolo tse fapaneng.Slide e ka holimo e ka sebelisoa ho fetola li-taper tse khutšoane ka boikemelo.The slide e ka holimo e ka boela ea sebelisoa ho kenya li-taper tse telele ha li tsamaisana le lijo tsa longitudinal tsa koloi.E ka boela ea finyella litlhoko tsa ts'ebetso ea ho cheka, ho bora le ho etsa trepanning.E boetse e loketse ho reteleha ho matla ka lisebelisoa tsa carbide, Ho sebetsana le litšepe tse fapaneng tsa ferrous le tse se nang ferrous.

-

rapameng enjene tloaelehileng lathe CW61126-CW611206

Letoto lena la li-lathes tse tloaelehileng tsa enjene li 'nile tsa ntlafatsoa le ho ntlafatsoa khafetsa ke k'hamphani ea rona ka lilemo tse fetang 40, ka mor'a ho kenngoa ha moralo o tsoetseng pele le theknoloji ea tlhahiso lapeng le linaheng tse ling, le ka mor'a tšebeliso ea basebelisi sebakeng sa lifofane, terene, valve le liindasteri tse ling, tloaelo e pakile hore lithapo tse kholo tse tšekaletseng tse hlahisoang ke k'hamphani ea rona li fihlile maemong a holimo China.

Likarolo tsa tekheniki tsa letoto lena la li-lathes ke tse latelang: pele, likarolo tsa motheo, quill ea spindle tailstock, joalo-joalo li fetisitse moralo oa ts'ebetso le ts'ebetso e ntle, ka ho nepahala le bophelo bo phahameng;ea bobeli, likarolo tsa bohlokoa, tse kang li-spindle bearings le likarolo tse kholo tsa motlakase, kaofela ke lihlahisoa tse tummeng lapeng le linaheng tse ling.

-

enjene lathe, tloaelehileng lathe C6236

Letoto lena la lathe ea enjene e lebelo le phahameng le ka etsa mesebetsi e fapaneng ea ho phethoha, joalo ka ho fetola libaka tsa cylindrical tsa kahare le kantle, libaka tse boreleli, lifahleho tsa pheletso le likhoele tse fapaneng - likhoele tsa metric le inch, hammoho le ho cheka, ho rema le ho taka li-grooves tsa oli.Sesebelisoa sena sa mochini se ka sebetsana le tšepe, tšepe ea tšepe le litšepe tse se nang ferrous.Ho nepahala ha likarolo tse sebetsitsoeng ke lathe ena ho ka fihla ho IT6-IT7, 'me ho ka fumanoa ho fokola ho fokolang.Ho phaella mosebetsing oa ho fetola ka holimo, lathe ea saddle e loketse ka ho khetheha bakeng sa ho sebetsana le likarolo tsa disc le likarolo tse sa tloaelehang tse bōpehileng.

-

rapameng enjene lathe C6251-C6251V

A

Ponahalo e ncha

Ponahalo ea sebopeho sa lathe e kopanya mohopolo oa ergonomics ho sebopeho sa sesebelisoa sa mochini o holileng ho ntlafatsa maikutlo a ts'ebetso.Likarolo tse tsotehang tse khubelu le tse bohlooho li sebelisoa bakeng sa likarolo tsa tšepe tse kholo, 'me phello e akaretsang e ntle.

B

Litlhaloso tse hlakileng

Lihlahisoa tsa li-CA li na le litlhaloso tse felletseng le mekhahlelo e fapaneng.Ho kenyeletsoa lathe e otlolohileng ea bethe, lathe ea bethe ea saddle le lathe e kholo ea bophara.

C

Qetella mesebetsi

Li-lathe tsa li-CA li ka sebelisoa bakeng sa ho fetola lifahleho tsa ho qetela, li-cylinders tsa ka hare le tsa ka ntle, li-conical surfaces le libaka tse ling tse potolohang tsa thepa e sa tšoaneng.Ts'ebetso e nepahetseng haholoanyane ea metric e fapaneng, inch, module, diametral pitch threads.Ho phaella moo, ho cheka, ho tsosolosa, ho hula li-grooves tsa oli le mesebetsi e meng le tsona li ka ba le bokhoni bo bonolo.

D

Tshebetso e babatsehang

The 40A letoto la lathe tloaelehileng a hlomelloa le bophara e khōlō spindle ka pele bering, 'me e na le bethe e pharaletseng span bapisoa le lihlahisoa tse tšoanang, ho finyella phahameng tlhophiso rigidity, e le hore tshebetso ya sehlahisoa fihla bophahamo bo bocha.

lisebelisoa tse tloaelehileng: Li-chuck tse tharo tsa mohlahare tse feto-fetohang le litsi Sethunya sa oli Lebokose la lisebelisoa le lisebelisoa 1 sete.