Litsela tse tharo tse tataisang mosebetsi o boima o rapameng oa CNC lathe C61200S letoto

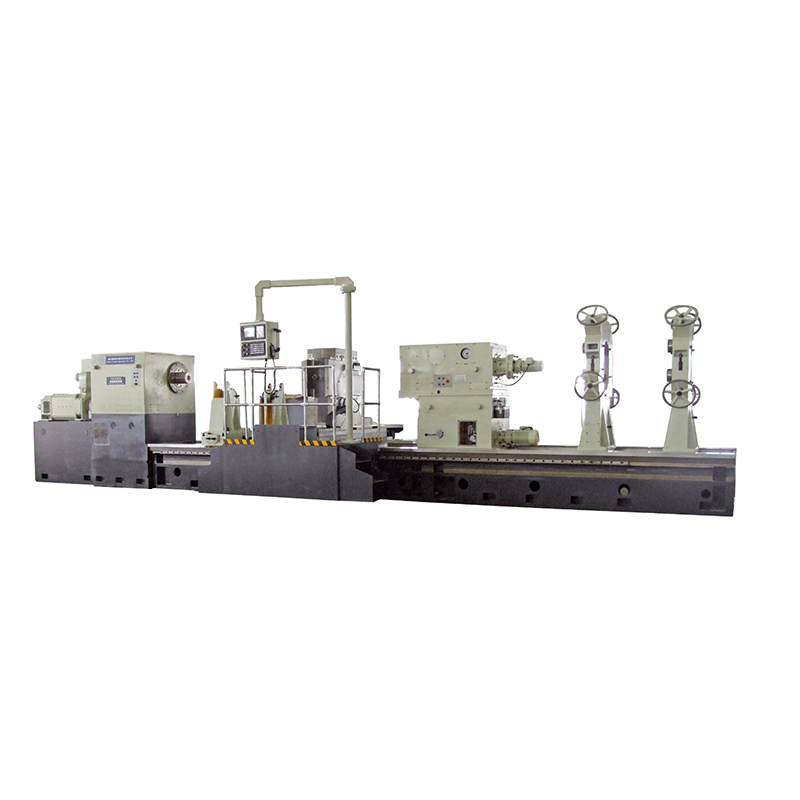

Sebopeho sa sehlahisoa

Letoto la C61xxS ke letoto le ntlafalitsoeng la li-lathe tse tšekaletseng tse boima tse ntlafalitsoeng ke k'hamphani ea rona ho ipapisitse le boiphihlelo ba rona ba nako e telele ba ho hlahisa lithapo tse otlolohileng le ho amohela mekhoa ea meralo e tsoetseng pele ea machabeng le theknoloji ea tlhahiso.Ke sehlahisoa se entsoeng hantle se kopanyang motlakase, taolo ea othomathike, taolo ea hydraulic, moralo oa morao-rao oa mochini le litloaelo tse ling Lihlahisoa tsa lisebelisoa tsa mochini oa Mechatronic tse kopanyang likarolo tse ngata tsa theknoloji ea tlhahiso e nepahetseng.Sebopeho le ts'ebetso ea sesebelisoa sa mochini lia sebetsa.Sesebelisoa sa mochini se na le litšobotsi tsa boima bo phahameng bo matla le bo tsitsitseng, bophelo bo bolelele ba ts'ebeletso, ts'ebetso e phahameng ea ts'ebetso, mesebetsi e bolokehileng le e tšepahalang, ts'ebetso e bonolo le ponahalo e ntle.

1. E loketse bakeng sa lisebelisoa tsa ho itšeha tse kang tšepe ea lebelo le phahameng le tšepe ea carbide e entsoeng ka samente, ho fetola selikalikoe se ka ntle, sefahleho sa ho qetela, grooving, ho itšeha le ho boring, li-cylinder le likarolo tsa disc tsa tšepe e entsoeng ka tšepe, tšepe e se nang tšepe le tse ling tse seng tsa tšepe. lisebelisoa.

2. Mokhoa o ka sehloohong oa ho khanna le ho fepa ke oa sebopeho se arohaneng.Sesebelisoa sa mochini ke lathe e otlolohileng e boima e nang le ts'ebetso ea ho laola lipalo.

3. Bethe e amohela mekhoa e meraro e tataisang, 'me tsela e tataisang ea bethe ea kariki e amohela kalafo ea quenching ea maqhubu a mahareng.

4. Koloi e kholo e tsamaisoa ke servo motor ea spindle, 'me lebelo le utloahalang la lebelo la spindle le lemohuoa ka phetoho ea lebelo la mechine e' meli.

5. Lebokose la li-headstock ke la lerako le nang le mekhahlelo e 'meli ka sebopeho sa shaft,' me le amohela mela e 'meli e khutšoanyane ea li-cylindrical roller e nang le mokhoa o phahameng oa ho fetola radial clearance.Ka moralo oa optimization, ho otloloha ho hoholo ha spindle le nako e nepahetseng ea ho jara lia amoheloa ho ntlafatsa ho nepahala ha potoloho le ho satalla ho matla le ho sa fetoheng.Bohareng bo holim'a spindle ho nka sebopeho sa mofuta o mokhuts'oane oa seqha sa flange, se ntlafatsang ho tiea ha khokahano lipakeng tsa setsi le seluloana.

6. Sesebelisoa sa poso se amohela sebopeho sa poleiti ea lisebelisoa tse otlolohileng, tse ka sebelisetsoang ho itšeha ka matla.Tataiso e otlolohileng e amohela sekoti sa bolo, 'me tataiso ea longitudinal e amohela rack e nepahetseng haholo le sebopeho sa ho tlosa meno a habeli.Sesebelisoa se seholo sa sesebelisoa se hokahane le shaft e otlolohileng ea lebokose la phepelo, e ntlafatsang ho nepahala ha phetisetso ea poso ea sesebelisoa.

7. The tailstock ke mohaho oa lebokose oa bohlokoa.The core shaft ka sleeve ke habeli mela e khutsoanyane cylindrical rolara e nang le ho nepahala ho phahameng le ho feto-fetoha ha radial clearance.Bohareng ke mofuta oa flange short taper shank center, e etsang hore tailstock e be le boima bo phahameng.Sleeve le tailstock li tsamaea ka mokhoa o tsamaeang, 'me li ka tlamelloa le ho lokolloa ka bohona ha li le teng.'Me e na le sesebelisoa sa ho lekanya matla a hydraulic.

8. Mokhoa oa ho laola lipalo o amohela tsamaiso ea SIEMENS, 'me lisebelisoa tse ling tsa ho laola lipalo kapa lisebelisoa tsa pontšo ea digital li ka boela tsa khethoa ke mosebedisi.

9. Ho ea ka litlhoko tsa basebelisi, re ka fana ka lisebelisoa tse peli tsa lisebelisoa, lisebelisoa tsa ho sila le tse bora, lisebelisoa tsa ho sila, joalo-joalo.

TS'OANELO MOHLOMI

| tlhaloso | Mohlala | ||

| C61200S | C61250S | C61315S | |

| Max.ho sotha bophara hodima bethe | 2000mm | 2500 limilimithara | 3150 limilimithara |

| Max.swing bophara hodima kariki | 1600 limilimithara | 2000mm | 2500 limilimithara |

| Bolelele ba workpiece | 6-25 limilimithara | ||

| Max.ho kenya boima pakeng tsa litsi | 63t | ||

| Diameter ea sefahleho sa sefahleho | 1600 limilimithara | 2000mm | 2500 limilimithara |

| Bophara ba bethe | 2150 limilimithara | ||

| Sekoti se ka pele sa lesoba la spindle | Mofuta o mokhuts'oane oa taper flange, taper 1:4 | ||

| Lebelo la lebelo la spindle, likere tse peli tsa mochini, tse se nang mohato lipakeng tsa likere | 0.63-125r/Mm haeteroliki likere tse peli, stepless | 0.5-100r/Mm haeteroliki likere tse peli, stepless | 0.5-100r/Mm haeteroliki likere tse peli, stepless |

| Longitudinal le transversal feed speed range of tool post | 1-500mm/Mots | ||

| Lebelo le potlakileng la longitudinal le le pharalla | 3000mm/Mots | ||

| Taper of quill of tailstock | Mofuta o mokhuts'oane oa taper flange, taper 1:4 | ||

| Max.leeto la quill of tailstock | 200mm | ||

| Matla a motlakase a ka sehloohong | AC110/AC125kW | ||

| Sistimi ea CNC | SIEMENS kapa tse ling, tse khethiloeng ke bareki | ||